Treasures from Long Ago

Covered bridges are a deeply loved emblem of Lancaster County. A tangible reminder of a slower-paced, long-ago era. An age of horses and carriages and Model T’s. A time when folks worked hard on their farms and mills and seemed to have more time for each other.

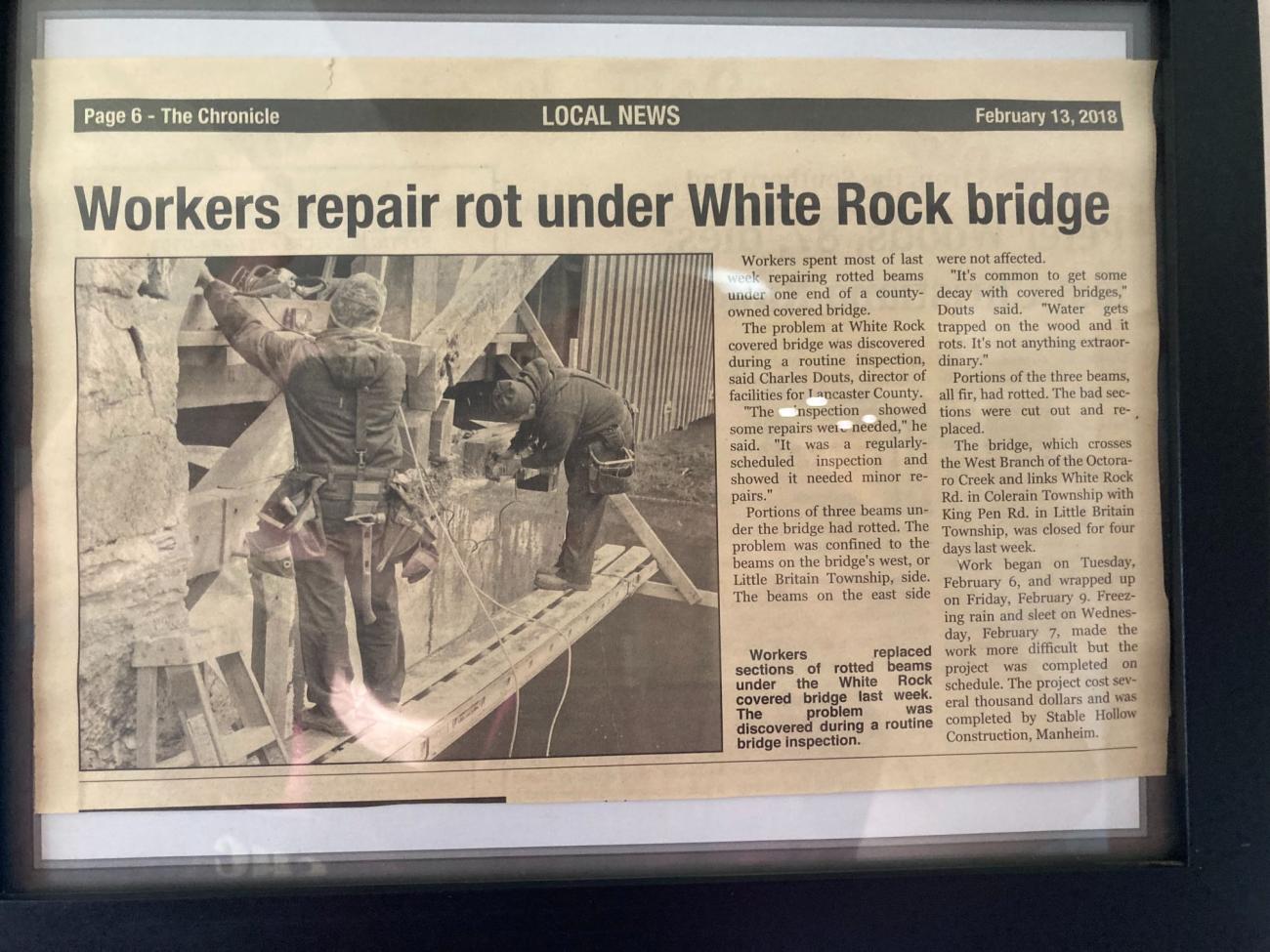

Stable Hollow Construction has had the privilege of teaming up with the committed residents and officials of Lancaster County to repair most of the 27 covered bridges still standing in the county.

Stable Hollow has repaired every part of a covered bridge. Roofs. Braces. Lower chords. Double arches. You name it. Sometimes a car accident, floodwaters, or normal wear and tear will be the culprit behind the damage. Whatever the reason, covered bridges usually need to be repaired quickly and efficiently since many of them are still open to local traffic today.

Locals often stop their cars and roll down their windows to ask what the team is doing on “their bridge.” They are tuned in to what goes on in their bridges and entirely devoted to protecting them from damage. Their passion for the bridges’ upkeep and preservation is touching and inspiring.

Enjoy the history of these two Lancaster County covered bridges, both repaired by Stable Hollow Construction.

Kauffman’s Distillery Bridge

Kauffman’s Distillery Bridge, located in Manheim, PA, is named for a distillery operated from 1794-1894 on the northern end of the village by two Kauffman brothers. In 1855, the local authorities asked a small crew of local citizens to assess the need for a bridge at this particular location. The committee agreed a bridge would create a more direct route between the small towns of Mount Joy and Lititz.

James C. Carpenter built the Burr Arch Truss bridge in 1857. In 1874, Elias McMellen—famous for designing many of the county’s covered bridges—rebuilt the bridge for $1,620. That price sounds unbelievable compared to the thousands of dollars that every replacement now costs today.

One memorable day, a too-tall box truck got stuck inside this bridge. To remove the truck, the response team had to let all the air out of the tires. In order to replace the broken ceiling beams, Stable Hollow removed the roof, replacing the cedar shakes (the traditional covered bridge roofing material) with standing seam metal. Though sentimentally disappointing, installing a quality metal roof is a practical part of the evolution of restoration.

Today, construction workers have installed a headache bar on the bridge’s portal, and modern vehicles regularly cross the creek through the bridge. Yet, a split rail fence leading up to the bridge and grassy banks on either side still gives the impression that you’ve entered a slower era from the past.

White Rock Forge Bridge

White Rock Forge Bridge—another bridge that Stable Hollow Construction has worked on considerably— holds claim to some fascinating history including a few fierce floods.

Completed in 1847 by Joseph Russell, the bridge resulted from the local citizens’ request for a more direct route between “the road from Oak Hill to Union Meetinghouse.” Built of oak planks and painted the traditional red color on the sides and white on the approaches, the bridge measures 110 feet in total length.

A violent storm swept it away in June of 1858 and then again in 1884 when the Octoraro Creek crested higher than ever before. Known as one of the finest bridges around, the local folks gathered remnants from the broken bridge and built a temporary bridge for 47¢, the cost of the nails. For $2,495, Elias McMellen rebuilt the bridge for the third time in the following weeks.

The Slumbering Groundhog Lodge of York sits next door to the bridge. The lodge members cross the bridge in a parade every year before Octarora Orphie famously predicts whether spring will arrive early that year.

Covered Bridge Restorations

When it comes to covered bridge restorations, Stable Hollow never knows what might need to be repaired next. Here are a few examples of common repair and maintenance needs.

- Tie beams, portal beams, and angle braces typically take the brunt of car accidents. Many other braces and arches have been repaired too.

- Arch bottoms and summer beams are a common place for natural deterioration as they normally sit on the concrete buttress or “head wall” of the bridge. Since most Lancaster County covered bridges are designed with the double burr arch, Stable Hollow has created a system to easily remove one side of the arch while working on repairing or replacing the other side.

- Headache bars are a safety precaution added to many bridges. One bridge needed three repairs in six months due to oversized vehicles trying to cross. Finally, Stable Hollow installed headache bars to hopefully prevent the same mistake from happening the fourth time.

- Stable Hollow’s skilled mason team has repaired the stonework outside the bridges on occasion.

- Stable Hollow’s goal is to preserve history and keep the bridges as original-looking as possible. But there are times when practicality wins. For example, the siding on covered bridges traditionally hung 8 inches past the bridge’s bottom. Too often, storm waters have torn the siding from the structure. Today, the siding is normally cut even with the bottom of the bridge.

- Covered bridges have four layers of floor structure to help with the bridge’s flexing. When replacing floorboards, Stable Hollow installs them in 10-foot sections to allow more flex.

- Depending on the amount of work required on the underside of a covered bridge, Stable Hollow uses jacks to lift the bridge entirely off its foundation. Sometimes they will also pour concrete pads for extra support while they work.

Looking Forward

Covered bridges are an iconic symbol of Lancaster County’s rich history. They are also a scenic testament to the beauty that still surrounds its residents today. Stable Hollow considers it a tremendous privilege to maintain these bridges. May they live on for years to come!

List of Bridges Worked on by Stable Hollow Construction

Leaman Place (Eshelman’s Mill)

By Photo by and (c)2007 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Neff’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Lime Valley

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Baumgardener’s

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Forry’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Own Picture. Cropped from the original., CC BY-SA 2.5

Siegrist’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Schenck’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Kauffman’s Distillery

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Zook’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Erb’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Keller’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

White Rock Forge

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Colemanville

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Shearer’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Hunsicker’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Bitzer’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Weaver’s Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5

Landis Mill

By Photo by and (c)2006 Derek Ramsey (Ram-Man) – Self-photographed, CC BY-SA 2.5